The purest Magnesium Carbonate is used as starting material for the manufacture of Magnesium Oxide. As a result there is low presence of Arsenic, Lead, Mercury, Cadmium and Aluminium.

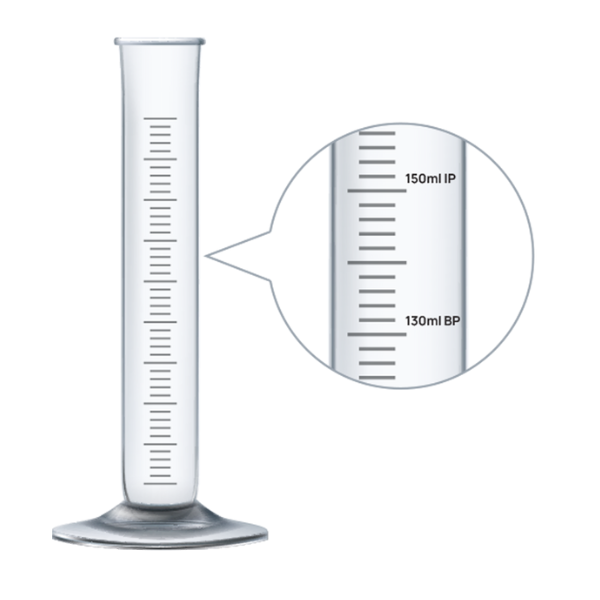

- Light Magnesium Oxide IP

- Light Magnesium Oxide BP

- Heavy Magnesium Oxide IP

- Heavy Magnesium Oxide BP

- Magnesium Oxide USP

- Magnesium Oxide DC

- Magnesium Oxide FCC

The calcination of Magnesium Carbonate to Magnesium Oxide has the chemistry: MgCO3 —--> MgO + CO2 (ΔH = +118 kJ/mol).

The calcination process has been custom designed by us. The process is fully automated with zero manual control. This benefits you because there is zero presence of foreign and metallic particles in the Magnesium Oxide. Additionally, the highly automated process results in low Loss on Ignition data. Hence you get high assays and purity of Magnesium Oxides.

The Magnesium Oxides manufactured by us, meet all your mesh size and bulk density requirements. To aid your rapidly changing formulation requirements, we have been successful in retrofitting our processes to meet bulk density requirements ranging from 0.08 gm / cc [gm / ml, kg / litre ] to 1.0 gm / cc [ gm / ml, kg / l ]. This capability will encourage you to trust us when challenging specifications are required.

Magnesium Oxide DC

Our DC grade Magnesium Oxide is made from our own rigorously tested Magnesium Oxide powder. The granulation is done in highly accurate and validated GMP SS 316 Roll Compactor machines. The process is flexible enough for the manufacture of all ranges of DC grade Magnesium Oxides.

The intrinsic properties of Flowability and Angle of Repose remain an industry best. We encourage you to engage with our production team for highly challenging mesh size and bulk density requirements.