At Rhine Laboratories, we manufacture

the following grades of Magnesium Carbonate

- Light Magnesium Carbonate IP

- Light Magnesium Carbonate BP

- Light Magnesium Carbonate BP / Ph. Eur.

- Heavy Magnesium Carbonate IP

- Heavy Magnesium Carbonate BP

- Heavy Magnesium Carbonate BP / Ph. Eur.

- Magnesium Carbonate USP

- Magnesium Carbonate FCC

- Magnesium Carbonate DC Grade

Our Magnesium Carbonates are manufactured from rigorously tested raw materials, namely Sodium Carbonate and Magnesium Chloride. The process chemistry is: MgCl2 + Na2CO3 = MgCO3 + 2NaCl

Raw Materials are extensively tested to ensure low levels of Lead, Arsenic, Nickel, Mercury, Cobalt, Vanadium and Fluoride in our Magnesium Carbonates.

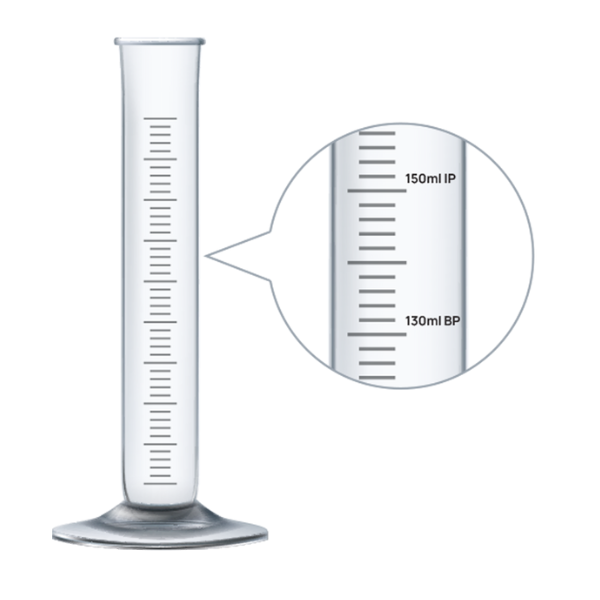

You get to source customised bulk densities of Magnesium Carbonates from us. The bulk densities range from 0.05gm / cc [ gm / ml, kg / litre ] to 0.70 gm / cc [ gm / ml, kg / litre]. Our Magnesium Carbonate USP has unlimited bulk density combinations to suit your formulations.

Magnesium Carbonate DC

We are an industry first in the manufacture of Magnesium Carbonate DC grade. The most accurate GMP grade Roll Compactor machines are used for this process. The machines have been custom designed by our R & D team in consultation with the machine manufacturer.

The granules are of regular size with industry best compressive strength. They have excellent properties of Flowability and Angle of Repose. Your compaction process will greatly benefit from our DC grade Magnesium Carbonate. There will be minimal loss of Magnesium Carbonate due to low powder generation during tableting. The regular grain size will improve the flowability of your mineral mixtures.